Publisher: Administrator Date: 2025-07-04

The core advantages of precision dispensing valves in dispensing machines

High precision and high efficiency

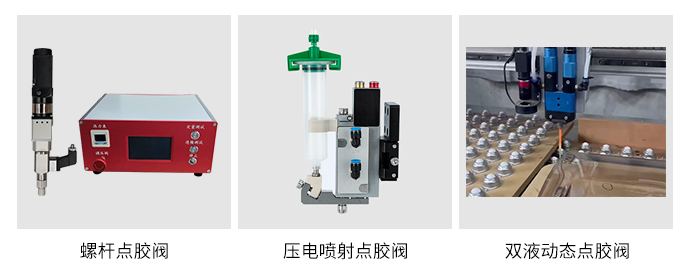

Piezoelectric injection valve has instantaneous response, fast switching speed, and crisp and clean injection without trailing; Glue dots as small as the diameter of hair strands, suitable for chip packaging and dispensing of micro components; Proficient in handling low to medium viscosity fluids such as UV glue and conductive glue.

Screw valve adhesive quantity control is stable with small fluctuations, especially suitable for high viscosity adhesives (such as silicone grease and epoxy resin); Expert in gap filling, precise control of adhesive amount, perfect filling of 0.2mm narrow gaps (such as phone frame sealing); Special material flow channel is resistant to particle wear and has a long service life.

Wide adhesive adaptability

Viscosity compatibility: The piezoelectric valve supports adhesives ranging from 0-200000 CPS (such as UV glue and anaerobic glue); Screw valves are compatible with abrasive adhesives containing particles, such as silicone grease and epoxy resin.

Special fluids: Conductive adhesive, instant dry adhesive require diaphragm valve to prevent solidification; The two-component adhesive must be dynamically mixed with dual liquid valves.

Durable and easy to maintain design

The valve body adopts ceramic stator and corrosion-resistant flow channel; Aviation grade materials (such as titanium alloy) reduce high-frequency wear and have a lifespan of over a million cycles. The modular structure supports quick replacement of nozzles/screws and simple cleaning.

Core application scenarios

Electronic Manufacturing

Chip packaging: The piezoelectric valve is like a "miniature injector", precisely targeting components the size of rice grains to avoid glue overflow and damage to precision circuits.

Circuit board soldering: A specialized solder paste valve sprays solder joints smaller than sand particles, quickly sticking the phone shielding cover and ensuring zero signal interference.

Display panel

Phone border sealing: The screw valve is like a "steady paintbrush", evenly applying UV glue to draw a perfect waterproof line on the screen border, without scratching the glass.

Folding screen reinforcement: dynamically control the amount of adhesive to make the adhesive layer at the hinge of the folding screen as thin as cling film, bending tens of thousands of times without cracking.

New energy batteries and photovoltaics

Battery sealing: The linear motor-driven dispensing head is "as fast as a sewing machine", and can apply 1 meter of battery sealant in 1 second, which is earthquake resistant and leak proof.

Photovoltaic modules: Temperature controlled dispensing valves operate on high-speed assembly lines (500mm/s), accurately packaging 1000 solar panels per hour

Choose Suggestions

To be fast, accurate, and small droplets: choose a piezoelectric spray valve.

Apply high viscosity adhesive/containing particles, fill narrow gaps, and seek stability: use screw valves.

Used for mixing two different adhesives, AB glue, epoxy resin, etc. that require rapid curing, using a two-component mixing dynamic screw valve.